Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Material World is a weekly roundup of innovations and ideas within the materials sector, covering news from emerging biomaterials and alternative leathers to sustainable substitutes and future-proof fibers.

Columbia’s Omni-Shade Sun Deflector technology is engineered to deflect the hot rays of the sun and is featured on several warm-weather products, including the Summit Valley Long Sleeve shirt.

Columbia Sportswear

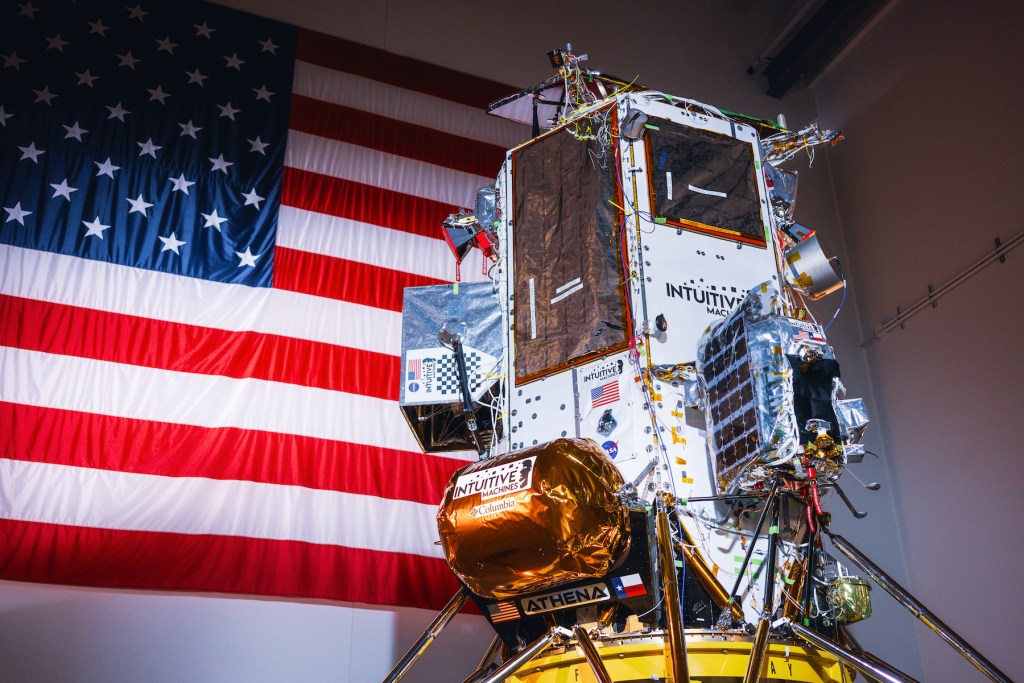

Columbia Sportswear has expanded its partnership with space exploration company Intuitive Machines ahead of its second lunar launch later this month.

The apparel firm’s Omni-Heat Infinity and Omni-Shade Sun Deflector insulation technologies will be used to protect the traveler from the extreme temperatures in space and on the Moon, following last year’s successful mission that incorporated Columbia’s Omni-Heat Infinity insulation technology.

The two have worked together to design and test thermal management materials that fully integrate Columbia’s Omni-Heat Infinity technology, plus an additional technology called Omni-Shade Sun Deflector, into the IM-2 lander, Athena. The former is a heat-reflective insulation for cold temperatures, while the latter shields the sun’s extreme heat.

“During the IM-1 mission, we demonstrated the insulative power and durability of our Omni-Heat Infinity technology to help protect the lander—the same insulation used in our winter jackets and gear. While we celebrated this historic moment, we knew it was just the first step in unlocking the true potential of Columbia’s patented innovations,” said Haskell Beckham, vice president of innovation at Columbia Sportswear. “Through this scientific partnership, we have been able to stretch the boundaries of material and product testing to the furthest frontiers, reinforcing our commitment to delivering some of the most innovative outdoor solutions in the world.”

Columbia’s Omni-Shade Sun Deflector patented material will be integrated into a multilayer insulation blanket covering the lander’s top deck. Columbia’s technology will help keep the lander cooler to prevent overheating by reflecting solar radiation away from Athena’s batteries and avionics. The Omni-Shade Sun Deflector material uses reflective dots of titanium dioxide to deflect the sun’s heat away from the body.

“We proudly join Intuitive Machines on this second historic lunar mission, furthering their goal to return humans to the Moon, and lending our engineered materials to the cause,” said Joe Boyle, brand president at Columbia Sportswear. “From our headquarters in Portland, Oregon, all the way to the surface of the Moon, we can confidently say our products undergo the most rigorous testing to ensure they meet the highest standards of performance. This partnership has allowed us to fearlessly experiment and employ our technologies in the most extreme environments, advancing our shared commitment to human exploration on Earth and beyond.”

As it did for the IM-1 mission, Columbia’s Omni-Heat Infinity technology will be used again, this time to insulate the helium tank on Athena, which will help protect against extreme temperatures.

“Space and Earth are part of an innovation ecosystem where progress in one fuels advancement in the other,” said Steve Altemus, president and CEO of Intuitive Machines. “By continuing our partnership with Columbia Sportswear, we’re proving that commercial innovation can break engineering barriers, supporting new industries on the Moon while driving technological advancements that reshape markets on Earth.”

The automated assembly to disassembly process, supported by thermoreversible adhesives.

Courtesy

Automated apparel manufacturing company CreateMe and leading UK institution the University of Warwick announced a proprietary thermoreversible adhesive following three years of R&D. The duo’s breakthrough is backed by 19 patents—encouraging evidence for the partnership to scale textile recycling.

This tech delivers the allegedly first fully automated, scalable disassembly for apparel that preserves the original materials’ utility, quality and value.

“CreateMe is uniquely positioned to transform how apparel is made. Our thermoreversible adhesive science paves the way for enhanced recycling opportunities, as part of our overall automated assembly manufacturing process, producing apparel in-market and on-demand,” said Cam Myers, CreateMe’s founder and CEO. “The timing could not be greater with the extended producer responsibility legislation currently being enacted in Europe and in certain U.S. states that bring enhanced requirements for end-of-life management of apparel products. This is a game changer for enabling the wider adoption of locally produced apparel and to facilitate recycling.”

Reversible adhesive is important for a few reasons.

These are glues that can be undone, so to speak, using water or heat or chemicals. Typically, these garments require manual de-stitching or the use of permanent adhesives, which render disassembly null and void. Thermoreversible adhesive, however, can be reversed through a controlled process.

Integrated within CreateMe’s advanced robotic systems, this proprietary adhesive uses a Diels-Alder reaction, a useful trick of sorts that chemists deploy to build more complex molecules. Imagine two mismatched blocks that join together in one smooth move to form a closed loop of links into a hexagon-shaped ring.

That reaction enables thermoreversible cross-linking, which can be visualized as a glue that links and unlinks mismatched blocks based on temperature. Cold connects, hot breaks apart. Particularly interesting as traditional thermoplastic and thermoset adhesives cannot recycle or reshape materials in a relatively simple way. Unlike conventional adhesives, this adhesive is reportedly strong enough for assembly and weak enough for breakdown—a prerequisite for recycling and circularity. More specifically, the apparel assembly process uses a hot melt adhesive dispense system and proprietary bonding methods to join the adhesive and fabric.

“This collaboration demonstrates how materials science and automation can converge to address global sustainability challenges,” Remzi Becer, a professor at the University of Warwick, said. “The potential applications extend far beyond fashion, impacting industries such as healthcare, automotive, aerospace and home goods.”

The initial focus remains on cotton and low-spandex polyester blends—for now—as the partners have validated durability and strength comparable to existing adhesives.

Previously known as BIO Waterproof and BIO Windproof, eVent stormST and windstormST deliver the same plant-based/ePTFE-free performance.

Courtesy

Global leader in waterproof and breathable technology eVent Fabrics renamed its plant-based “Bio Waterproof” and “Bio Windproof” laminates to “StormST” and “WindstormST” for the Spring/Summer 2026 season.

“We introduced eVent ‘Bio’ in 2016, pre-Covid, and perhaps before the market was ready for it,” said Chad Kelly, president of eVent Fabrics. “With our increased focus in offering a variety of high-performance sustainable laminates, we felt that ‘Bio’ might, at this point, be a bit confusing.”

Beginning this month, the company will cease promoting and supplying all Bio-branding assets, including Bio Footwear, which will also be StormST, and will work with brand partners to facilitate a smooth transition. StormST and Windstorm ST will be introduced to the materials sourcing industry at Performance Days in Munich this March.

“We’ve noticed the term ‘bio’ showing up in a lot of marketing materials across consumer markets, and we felt its meaning had become diluted. Recognizing that this dilution could cause confusion for both brands and consumers, we opted to update our product names to create further differentiation,” Kelly said. “The new names, StormST and WindstormST, are a more natural fit for our product architecture, better highlight the laminates’ weather protecting performance, and speak more strongly to our new tagline ‘defy the elements.’”

The Orra Bag is 3D-printed using Balena’s BioCir Flex3D material and “bridges the gap between raw beauty and futuristic craftsmanship,” Balena said.

Balena

Next-gen materials science company Balena has teamed with designer Ovidiu Bojor for Paris Fashion Week on the launch of the Orra Bag.

The Orra is a 3D-printed design inspired by natural landscapes. The purse was made with Balena’s BioCir Flex3D filament material, which is biobased, recyclable and compostable. BioCir Flex3D is a biobased, compostable polymer material made for 3D printing. The material has flexibility comparable to TPU while remaining biodegradable as a single biobased material.

“Ovidiu Bojor’s 3D-printed Orra bag breaks free from conventional design norms, embracing a sculptural, organic aesthetic that draws inspiration from the textures and forms of natural landscapes,” Balena said. “Moving beyond the ordinary, Bojor emphasizes versatility and functionality, creating a piece that seamlessly adapts to modern lifestyles. The bag’s flowing contours and tactile layers evoke a timeless connection to nature, reimagining what sustainable design can look and feel like.”